Proactive maintenance - balancing - shaft,- and belt pulley alignment service

I support with my service the proactive maintenance of your machinery.

Service offer:

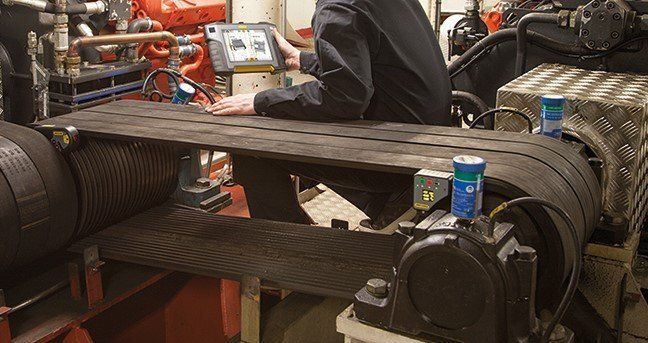

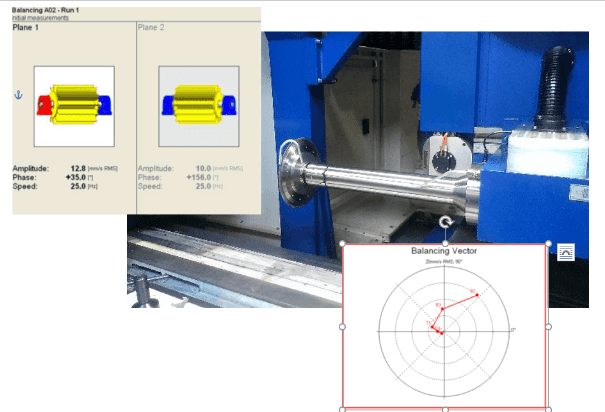

1. The balancing of static - and dynamic imbalances in the installed state on site.

The work will be carried out taking into account the relevant regulations and logged with a report.

Prerequisite is (in particular to check beforehand for the first time):

- The rotor is accessible for attaching weight or reduction

- One or two vibration sensors can be installed at the

bearings

- A speed sensor can be installed

- The machinery is sufficiently secured electrically and

mechanically against unintentional reconnection by

the customer

- The work area must be secured by the customer

accordingly

- Qualified technical personnel is provided by the customer

for support

- An approved welder for potential welding work is to

provide by the customer

Details are to clarify as best as possible before carrying out the work in order that the downtime is as low as possible.

If you send me information about the type of machinery (rotating component), speed, rotor weight, drive power, whether, - and how was balanced in the past, I can prepare work accordingly.

2. Shaft,- chain- and belt pulley alignment

Prerequisite is (in particular check at first implementation):

- Disclosure of shaft and coupling flange diameters

- Free for installation of sensors accessible axial dimension

of both shafts

- Possible interference contours in the rotation range of 180

° of the laser sensor (Radius coupling + 50mm)

- Drive power of the machine

- Thread size of the fixing screws. Up to M27 adapter plates

for vertical compensation are available in the Service

van.

- To adequately secure the system against unintentional

restart by the customer

- The work area must be secured by the customer

accordingly

- Qualified technical personnel is provided by the customer

for support

Details are to clarify as best as possible before carrying out the work in order that the downtime is as low as possible.

If you also provide me with information about the machinery type, speed, drive power, coupling type and desired tolerance, I can prepare work accordingly.

3. Alignment of foundations and machine frames

- The distance lengths must be known

- Foundation material should be known

- For machinery frames a drawing should be forwarded